Nagao Kanekoma - Kitchen knife - (Higo no Kami) - Steel, Blue Steel Warikomi - Japan - Japanese HIGONOKAMI

Owned an antiques and curio shop with a large international network.

Bidder 1518 Bidder 1518 | €45 | |

|---|---|---|

Bidder 6506 Bidder 6506 | €40 | |

Bidder 1518 Bidder 1518 | €25 | |

Catawiki Buyer Protection

Your payment’s safe with us until you receive your object.View details

Trustpilot 4.4 | 121798 reviews

Rated Excellent on Trustpilot.

Description from the seller

An Authentic Masterpiece of Japanese History and Craftsmanship

This original HIGONOKAMI (Higo no Kami) folding knife is handcrafted by Nagao Kanekoma, the last remaining blacksmith in the world officially authorized to use the name "Higonokami".

Born in the late 19th century, the Higonokami quickly gained popularity throughout Japan. In 1899, the Higonokami Knife Union was founded, a consortium bringing together over 40 manufacturers and more than 200 artisans.

In 1910, to defend against the growing number of low-quality imitations, the name “Higonokami” was officially registered as a trademark, reserved exclusively for members of the Miki Knife Manufacturers Association.

In the 1950s, public campaigns against carrying knives caused a drastic decline in the industry. All manufacturers shut down—except one: Nagao Kanekoma, who still keeps this historic tradition alive today.

The Essence of the Higonokami Knife

This model represents one of the most classic versions:

Hand-forged blade (刃身 – Jinbu), 75 mm in length, with a spine thickness (背 – Se) of 3 mm.

Sanmai structure (three layers), featuring a core of Blue Steel Warikomi, known for its excellent edge retention, and softer outer layers that provide flexibility and strength.

Cutting profile (切刃 – Kireha) with a double-beveled V-grind, and an extremely sharp edge (刃 – Ha), with a hardness of 62–65 + HRC.

(Aogami - Blue Paper Steel - is a pinnacle of Japanese craftsmanship and one of the highest carbon-content steels available on the market. This gives it exceptional hardness - it can reach up to 66 HRC - but also makes it prone to rust if not properly maintained. It should always be dried after use and kept away from humid environments.)

Solid brass handle (柄 – E), 9.5 cm in length (7 mm at its widest point), perfectly balanced and faithful to the traditional design. When open, the knife reaches a total length (blade + handle) of approximately 17 cm.

Friction-folding opening system, without a locking mechanism, featuring the traditional rear thumb lever Chikiri (チキリ) for a smooth and intuitive opening.

Note: Only one sample knife was photographed. Since each knife is entirely handcrafted, slight aesthetic differences may occur. Every piece is unique and one of a kind.

Authentic, Not an Imitation – Here’s Why It Really Matters

For those unfamiliar with Japanese cutlery, it can be difficult to immediately tell a genuine Higonokami from a simple copy.

And yet, the difference is real — and tangible, especially when you have the chance to see and hold the knife in your hands.

Unfortunately, with online purchases, this kind of evaluation becomes more complicated.

However, there’s one key indicator that should not be overlooked: an authentic Higonokami cannot be sold for just a few dozen euros.

Online, you can find knives priced so low they wouldn’t even cover the import duties from Japan — which alone can reach up to 30% of the factory value.

It’s worth giving serious thought to this fact.

How to Recognize the Original at a Glance

Kashime (カシメ) – The central rivet is tight, well-finished, and applied using traditional techniques. On imitations, it is often loose or replaced by a hex screw.

Brass Handle – Solid and heavy, it features a distinctive "V"-shaped curve at the start of the grip that gradually narrows toward the central rivet (Kashime). On fakes, the handle tends to be more uniform and often has a "U" shape.

Handle Engraving – Clear, deep, and well-proportioned. On counterfeits, it often appears blurred, shallow, or uneven.

Signed Blade – Made from high-quality steels such as Shirogami (white paper steel) or Aogami (blue paper steel). Copies usually use low-grade steels with poor edge retention.

These are the main clues for spotting the most obvious fakes.

However, there are also more sophisticated copies that are much harder to identify.

That’s why, when buying online, the price — along with the seller’s reputation and reliability — remains one of the most trustworthy indicators for recognizing a genuine Higonokami.

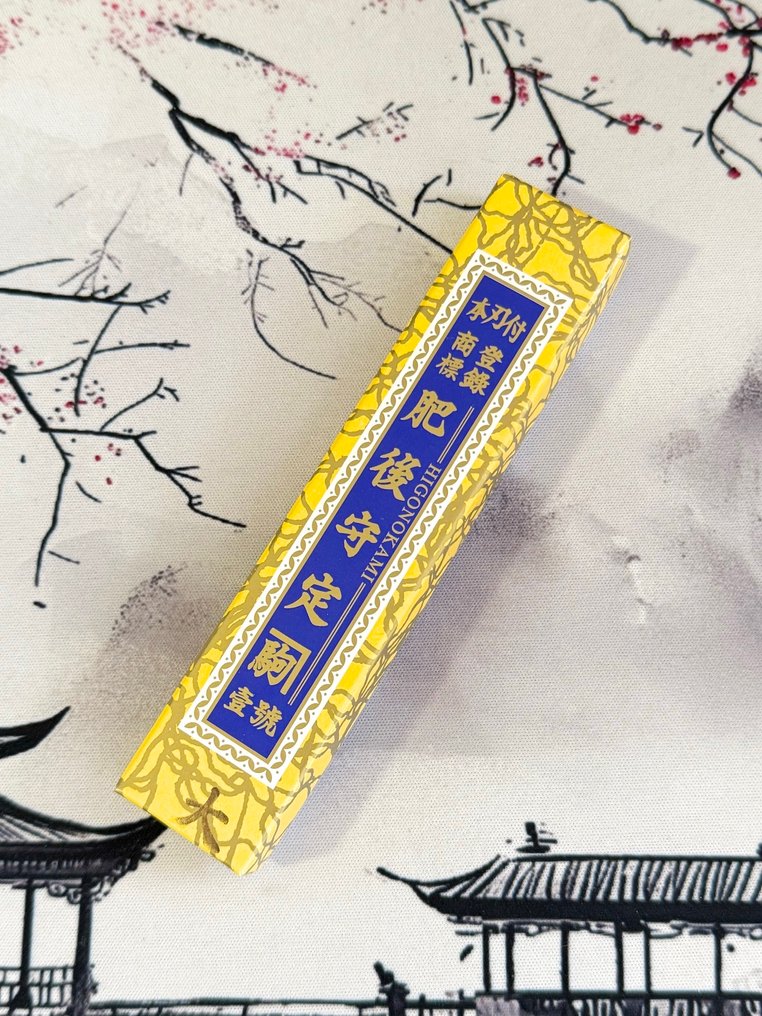

Each knife is presented in its traditional cardboard box, complete with the manufacturer's details, which acts as a certificate of authenticity.

You can also visit the official Nagao Kanekoma website (note: it does not sell online - higonokami.jp) to compare your knife with the models listed in the Aogami Warikomi section.

Offered by an Enthusiast

As a passionate collector of Japanese craftsmanship, I personally select only original and handmade knives from the finest blacksmiths in Seki, Miki, and Sakai.

This item is shipped from Monaco, in its original box (import taxes from Japan are already paid), using trackable, secure, and protective packaging.

Parts of a Higonokami Knife

For those who wish to understand every technical detail, here is the traditional Japanese terminology for the main parts of the knife:

チキリ (Chikiri) – Opening lever: small rear tab for thumb-operated opening

背 (Se) – Spine: top edge of the blade

宗 (Mune) – Ridge: spine line that gives the blade its silhouette

切先 (Kissaki) – Tip: pointed end used for precision cuts

刃 (Ha) – Edge: sharpened part of the blade

切刃 (Kireha) – Bevel: the angle forming the cutting geometry

カシメ (Kashime) – Rivet: central pin joining the blade to the handle

鞘 (Saya) – Handle: in this case made of brass, replacing the sheath in modern versions

Warnings:

The blades are extremely sharp: use with care and responsibility.

Hand-wash only, and dry thoroughly after use to prevent rust and handle damage.

Maintenance – Adjusting the Kashime

If the rivet is loose: place the knife on a hard surface and gently tap the rivet with a hammer to tighten it.

If it's too tight: hold the knife with the Chikiri facing down and lightly tap it against a table to loosen it.

Each knife is unique. Movement and resistance may vary slightly from piece to piece.

Recommended Sharpening

Sharpen only when necessary, using high-quality water stones, with the following grit ranges:

80–400 JIS: for significant edge damage

600–800 JIS: for edge refinement

1000–3000 JIS: for edge restoration

4000–8000 JIS: for polishing

Practical tip: a grit between 800 and 1200 JIS is ideal to maintain the edge with minimal effort.

The Roots of a Japanese Cutting Icon

1880s – The Hirata Knife

In Miki, Komataro Nagao began hand-forging knives using traditional techniques: steel embedded in iron, with handles made from brass or blackened iron.

Each knife was a miniature work of art, often decorated with floral motifs, portraits, or landscapes. Production was slow: only 5–8 knives per day.

1894 – The Birth of the Higonokami

Inspired by a folding knife from Kagoshima, wholesaler Tasaburo Shigematsu created a new model featuring a rear thumb lever, the Chikiri.

He named it “Higonokami” in honor of his many clients from Kumamoto (formerly the Higo province). It was an immediate success.

1910 – Trademark Protection

With increasing popularity came cheap knockoffs. The Higonokami Knife Union officially registered the name “Higonokami”, restricting its use to approved members.

1950 – Decline and Perseverance

The introduction of utility knives and anti-knife campaigns caused the market to collapse. Only Nagao Kanekoma continued the tradition.

1911 – Imperial Recognition

At the Kobe Export Exhibition, the future Emperor Taisho personally purchased a Higonokami knife.

That gesture greatly enhanced the knife’s prestige and spread its fame across Japan.

From 1894 to Today: A Living Legacy

Owning a Nagao Kanekoma Higonokami means holding a true piece of Japanese cultural heritage.

Five generations of master blacksmiths have preserved this tradition, making each knife a unique object, rich in history and craftsmanship.

Seller's Story

An Authentic Masterpiece of Japanese History and Craftsmanship

This original HIGONOKAMI (Higo no Kami) folding knife is handcrafted by Nagao Kanekoma, the last remaining blacksmith in the world officially authorized to use the name "Higonokami".

Born in the late 19th century, the Higonokami quickly gained popularity throughout Japan. In 1899, the Higonokami Knife Union was founded, a consortium bringing together over 40 manufacturers and more than 200 artisans.

In 1910, to defend against the growing number of low-quality imitations, the name “Higonokami” was officially registered as a trademark, reserved exclusively for members of the Miki Knife Manufacturers Association.

In the 1950s, public campaigns against carrying knives caused a drastic decline in the industry. All manufacturers shut down—except one: Nagao Kanekoma, who still keeps this historic tradition alive today.

The Essence of the Higonokami Knife

This model represents one of the most classic versions:

Hand-forged blade (刃身 – Jinbu), 75 mm in length, with a spine thickness (背 – Se) of 3 mm.

Sanmai structure (three layers), featuring a core of Blue Steel Warikomi, known for its excellent edge retention, and softer outer layers that provide flexibility and strength.

Cutting profile (切刃 – Kireha) with a double-beveled V-grind, and an extremely sharp edge (刃 – Ha), with a hardness of 62–65 + HRC.

(Aogami - Blue Paper Steel - is a pinnacle of Japanese craftsmanship and one of the highest carbon-content steels available on the market. This gives it exceptional hardness - it can reach up to 66 HRC - but also makes it prone to rust if not properly maintained. It should always be dried after use and kept away from humid environments.)

Solid brass handle (柄 – E), 9.5 cm in length (7 mm at its widest point), perfectly balanced and faithful to the traditional design. When open, the knife reaches a total length (blade + handle) of approximately 17 cm.

Friction-folding opening system, without a locking mechanism, featuring the traditional rear thumb lever Chikiri (チキリ) for a smooth and intuitive opening.

Note: Only one sample knife was photographed. Since each knife is entirely handcrafted, slight aesthetic differences may occur. Every piece is unique and one of a kind.

Authentic, Not an Imitation – Here’s Why It Really Matters

For those unfamiliar with Japanese cutlery, it can be difficult to immediately tell a genuine Higonokami from a simple copy.

And yet, the difference is real — and tangible, especially when you have the chance to see and hold the knife in your hands.

Unfortunately, with online purchases, this kind of evaluation becomes more complicated.

However, there’s one key indicator that should not be overlooked: an authentic Higonokami cannot be sold for just a few dozen euros.

Online, you can find knives priced so low they wouldn’t even cover the import duties from Japan — which alone can reach up to 30% of the factory value.

It’s worth giving serious thought to this fact.

How to Recognize the Original at a Glance

Kashime (カシメ) – The central rivet is tight, well-finished, and applied using traditional techniques. On imitations, it is often loose or replaced by a hex screw.

Brass Handle – Solid and heavy, it features a distinctive "V"-shaped curve at the start of the grip that gradually narrows toward the central rivet (Kashime). On fakes, the handle tends to be more uniform and often has a "U" shape.

Handle Engraving – Clear, deep, and well-proportioned. On counterfeits, it often appears blurred, shallow, or uneven.

Signed Blade – Made from high-quality steels such as Shirogami (white paper steel) or Aogami (blue paper steel). Copies usually use low-grade steels with poor edge retention.

These are the main clues for spotting the most obvious fakes.

However, there are also more sophisticated copies that are much harder to identify.

That’s why, when buying online, the price — along with the seller’s reputation and reliability — remains one of the most trustworthy indicators for recognizing a genuine Higonokami.

Each knife is presented in its traditional cardboard box, complete with the manufacturer's details, which acts as a certificate of authenticity.

You can also visit the official Nagao Kanekoma website (note: it does not sell online - higonokami.jp) to compare your knife with the models listed in the Aogami Warikomi section.

Offered by an Enthusiast

As a passionate collector of Japanese craftsmanship, I personally select only original and handmade knives from the finest blacksmiths in Seki, Miki, and Sakai.

This item is shipped from Monaco, in its original box (import taxes from Japan are already paid), using trackable, secure, and protective packaging.

Parts of a Higonokami Knife

For those who wish to understand every technical detail, here is the traditional Japanese terminology for the main parts of the knife:

チキリ (Chikiri) – Opening lever: small rear tab for thumb-operated opening

背 (Se) – Spine: top edge of the blade

宗 (Mune) – Ridge: spine line that gives the blade its silhouette

切先 (Kissaki) – Tip: pointed end used for precision cuts

刃 (Ha) – Edge: sharpened part of the blade

切刃 (Kireha) – Bevel: the angle forming the cutting geometry

カシメ (Kashime) – Rivet: central pin joining the blade to the handle

鞘 (Saya) – Handle: in this case made of brass, replacing the sheath in modern versions

Warnings:

The blades are extremely sharp: use with care and responsibility.

Hand-wash only, and dry thoroughly after use to prevent rust and handle damage.

Maintenance – Adjusting the Kashime

If the rivet is loose: place the knife on a hard surface and gently tap the rivet with a hammer to tighten it.

If it's too tight: hold the knife with the Chikiri facing down and lightly tap it against a table to loosen it.

Each knife is unique. Movement and resistance may vary slightly from piece to piece.

Recommended Sharpening

Sharpen only when necessary, using high-quality water stones, with the following grit ranges:

80–400 JIS: for significant edge damage

600–800 JIS: for edge refinement

1000–3000 JIS: for edge restoration

4000–8000 JIS: for polishing

Practical tip: a grit between 800 and 1200 JIS is ideal to maintain the edge with minimal effort.

The Roots of a Japanese Cutting Icon

1880s – The Hirata Knife

In Miki, Komataro Nagao began hand-forging knives using traditional techniques: steel embedded in iron, with handles made from brass or blackened iron.

Each knife was a miniature work of art, often decorated with floral motifs, portraits, or landscapes. Production was slow: only 5–8 knives per day.

1894 – The Birth of the Higonokami

Inspired by a folding knife from Kagoshima, wholesaler Tasaburo Shigematsu created a new model featuring a rear thumb lever, the Chikiri.

He named it “Higonokami” in honor of his many clients from Kumamoto (formerly the Higo province). It was an immediate success.

1910 – Trademark Protection

With increasing popularity came cheap knockoffs. The Higonokami Knife Union officially registered the name “Higonokami”, restricting its use to approved members.

1950 – Decline and Perseverance

The introduction of utility knives and anti-knife campaigns caused the market to collapse. Only Nagao Kanekoma continued the tradition.

1911 – Imperial Recognition

At the Kobe Export Exhibition, the future Emperor Taisho personally purchased a Higonokami knife.

That gesture greatly enhanced the knife’s prestige and spread its fame across Japan.

From 1894 to Today: A Living Legacy

Owning a Nagao Kanekoma Higonokami means holding a true piece of Japanese cultural heritage.

Five generations of master blacksmiths have preserved this tradition, making each knife a unique object, rich in history and craftsmanship.